Bagged Zinc Earthing Cell

Regarded as an earthing cell, zinc rod is commonly pre-packaged in the cotton bag filled with low resistivity backfill. Typically, two zinc anode units will be packed together —— one is connected to the protected structure, and the other is connected to an earthing device.

Additional information

| Application | Transmission Tower Foundation, Pipelines, Pylon |

|---|---|

| Environment | Fine Sand, Soil |

Description

Description

Quality Substrate Material

Our zinc anode is made from special high grade (SHG) zinc ingots with 99.995% purity. It is produced according to ASTM-B418 type I and type II alloy standards. The high-purity composition ensures the anode material is more resistant to passive films. Type I is generally used in seawater or brackish water, while Type II is used in underground and fresh water applications.

| Element | ASTM – B418 Type I | ASTM – B418 Type II |

| Aluminum (Al) | 0.1~0.5% | 0.005% max. |

| Lead (Pb) | 0.006% max. | 0.003% max. |

| Iron (Fe) | 0.005% max. | 0.0014% max. |

| Copper (Cu) | 0.005% max. | 0.002% max. |

| Cadmium (Cd) | 0.025% ~ 0.07% | 0.003% max. |

| Total Impurities | 0.1% max. | 0.1% max. |

| Zinc (Zn) | Remainder | Remainder |

High Current Output

Our zinc earthing rod anode can provide even distribution of current density to the cathode. Its self-regulating current output will not cause nor magnify stray currents present. With more than 90% current efficiency, its performance meets the highest industry standards.

| Technical Measurement | ASTM – B418 Type I | ASTM – B418 Type II |

| Open Circuit Potential (-V) | 1.05 min. | 1.10 min. |

| Close Circuit Potential (-V) | 1.00 min. | 1.05 min. |

| Current Capacity | 354A.h/lbs (780A.h/kg) | 335A.h/lbs (740A.h/kg) |

| Current Efficiency | 95% | 90% |

| Consumption Rate | 24.8 lbs/A·y (11.2 kg/A.y) | 26.2 lbs/A·y (11.9 kg/A.y) |

Remarks: Open/close circuit potential is with respect to a Saturated Calomel Reference Electrode.

Parameters

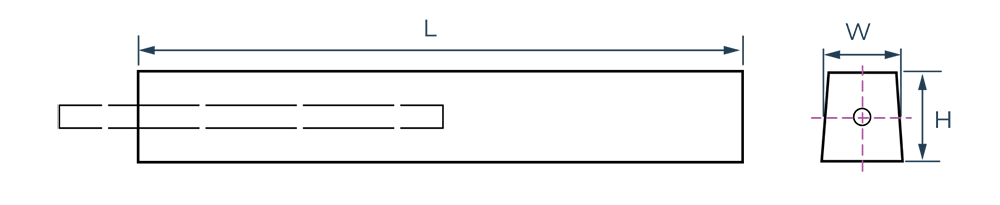

| Item No. | Anode Dimensions | Anode Qty. | Weight | |||

| W | H | L | Bare | Packaged | ||

| JA–ZC-E01 | 1.4” (35 mm) | 1.4” (35 mm) | 60” (1524 mm) | 2 | 60.0 lbs (27.2 kg) | 116.8 lbs (53 kg) |

| JA–ZC-E02 | 2.0” (51 mm) | 2.0” (51 mm) | 60” (1524 mm) | 2 | 120.4 lbs (54.6 kg) | 202.8 lbs (92 kg) |

| JA–ZC-E03 | 1.4” (35 mm) | 1.4” (35 mm) | 60” (1524 mm) | 1 | 30.0 lbs (13.6 kg) | 94.8 lbs (43 kg) |

Testing Details

We employ ISO 9001:2015 quality management system and rigorous internal testing standards to ensure the optimum lifespan and performance of our anodes. Each anode is labelled with a unique serial number for quality tracking.

| Technical Measurement | Chemical Composition | Electrochemical Performance | Physical Properties |

| Testing Standard | ASTM B418 | NACE TM0190 | Foundry ITP |

| Testing Content | Chemical Analysis | Circuit Potential / Current Capacity / Current Efficiency / Electrical Resistance | Dimensions & Weight / Surface Finish / Steel Core / Cable Connection / Backfill Packaging |

| Equipments | Optical Emission Spectrometer OBLF QSN 750 | Electrochemical Analyzer EPI 200 | Calibrated Digital Measuring Devices |

Packaging Information

Remarks: Custom packing is available upon request.

We have strict packing protocols to guarantee safe delivery of our products. Clear shipping marks and documentation make delivery acceptance straightforward and simple.

Shipping Documents:

- Proforma invoice

- Packing list

- Testing reports (Chemical Composition, Electrochemical Properties Test, Certificate of Compliance)

- Certificate of origin (upon request)