Square High Temperature Zinc Anode

It is known that common zinc alloys have a tendency to fail at temperatures above 60°C. Above this temperature, zinc alloys can suffer from intergranular corrosion, especially when buried in saline mud. When at high temperature, common zinc anodes may become ineffective or even detrimental to the iron and steel structure intended to be protected by the sacrificial CP system. The zinc anode suffers passivation and polarity reversal —— a dangerous condition in which zinc and steel reverse their natural polarity and steel becomes anodic to zinc, corroding itself and protecting the anode.

To meet the demand of anode applications at high temperature, we have developed this specialized zinc anode that can operate successfully at elevated temperatures up to 90°C.

Our high temperature zinc anode is designed for use in tanks intended for the carriage of liquid cargo with high temperature exposure, hot subsea pipelines and heat exchangers.

Additional information

| Application | Pipelines, Pylon |

|---|---|

| Environment | Brackish Water, Saline Mud, Seawater |

Description

Description

Quality Substrate Material

The superior electrochemical performance of the high temperature zinc anodes is ensured by carefully controlling the proportion of alloy elements added into the zinc substrate.

| Element | ≤ 50°C | 50°C ~ 90°C |

| Aluminum (Al) | 0.005% max. | 0.1% ~ 0.25% |

| Magnesium (Mg) | — | 0.05% ~ 0.15% |

| Lead (Pb) | 0.003% max. | 0.006% max. |

| Iron (Fe) | 0.0014% max. | 0.002% max. |

| Copper (Cu) | 0.002% max. | 0.001% max. |

| Cadmium (Cd) | 0.003% max. | 0.001% max. |

| Total Impurities | — | 0.1% max. |

| Zinc (Zn) | Remainder | Remainder |

Excellent Electric Capacity

The high temperature zinc anode capacity is tested in accordance with the criteria of DNVGL-RP-B401 standards.

| Technical Measurement | 20°C | 60°C | 80°C | 90°C |

| Closed Circuit Voltage (-V) | 1.03 | 1.01 | 0.98 | 0.95 |

| Current Capacity | 800 A.h/kg | 770 A.h/kg | 774 A.h/kg | 750 A.h/kg |

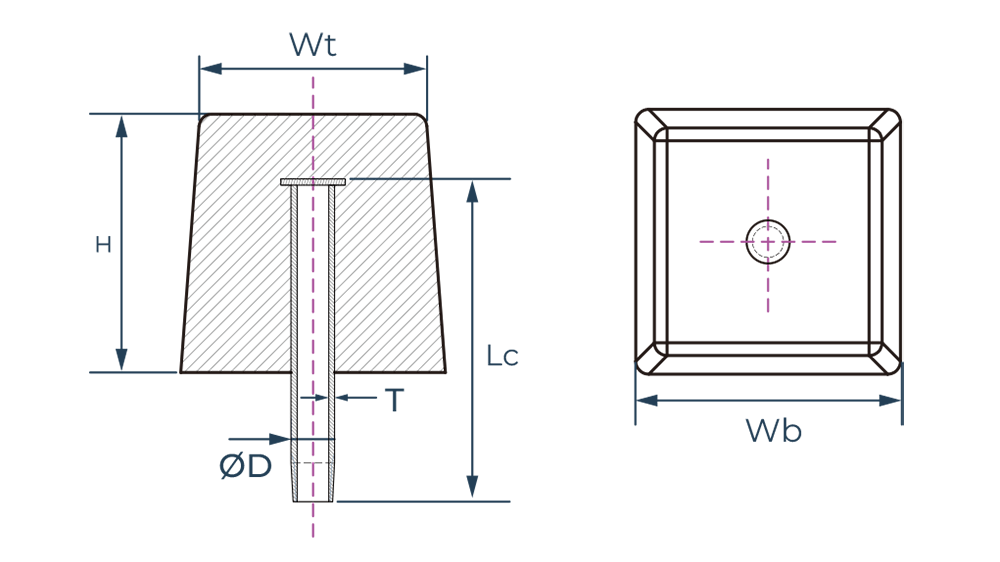

Parameters

| Item No. | Anode Dimensions | Insert Dimensions | Weight | |||||

| Wt | Wb | H | ØD | T | Lc | N.W | G.W | |

| JA-HTZ-S22 | 4.5” (115 mm) | 5.5” (140 mm) | 7.9” (200 mm) | 1.3” (33.4 mm) | 0.2” (4.5 mm) | 9.8” (250 mm) | 48.9 lbs (22.2 kg) | 50.7 lbs (23 kg) |

| JA-HTZ-S50 | 6.9” (175 mm) | 8.1” (205 mm) | 7.9” (200 mm) | 1.3” (33.4 mm) | 0.2” (4.5 mm) | 9.8” (250 mm) | 111.3 lbs (50.5 kg) | 113.1 lbs (51.3 kg) |

With the help of our experienced engineers, we can customize the anode size, inserts, service life and output current to meet your specific needs upon request.

Testing Details

We employ ISO 9001:2015 quality management system and rigorous internal testing standards to ensure the optimum lifespan and performance of our anodes. Each anode is labelled with a unique serial number for quality tracking.

| Testing Details | Chemical Composition | Electrochemical Performance | Physical Properties |

| Testing Standard | ATSM B418 | NACE TM0190 | NACE SP0387 / Foundry ITP |

| Testing Content | Chemical Analysis | Circuit Potential / Current Capacity / Current Efficiency / Electrical Resistance | Surface Finish / Dimensions & Weight / Steel Insert |

| Equipments | Optical Emission Spectrometer OBLF QSN 750 | Electrochemical Analyzer EPI 200 | Calibrated Digital Measuring Devices |

Packaging Information

Remarks: Custom packing is available upon request.

We have strict packing protocols to guarantee safe delivery of our products. Clear shipping marks and documentation make delivery acceptance straightforward and simple.

Shipping Documents:

- Proforma invoice

- Packing list

- Testing reports (Chemical Composition, Electrochemical Properties Test, Certificate of Compliance)

- Certificate of origin (upon request)