Bagged Magnesium Anode (D Type)

This prepackaged magnesium anode is composed of a cast magnesium anode centrally packed in a permeable cotton bag with a highly hygroscopic backfill containing a 75% gypsum, 20% bentonite and 5% sodium sulfate mix. Typically this assembly is then firmly wrapped in a PE bag or paper outer lining, for shipping purposes, which should then be removed prior to installation.

Efficiency of an anode can be further enhanced when pre-packaged in this depolarizing backfill. The specialized mixture lowers the anode-to-soil resistance, and allows electrical current to flow more easily to the targeted structure.

Our magnesium anode is assembled with the cable and joints sealed in with epoxy resin. Designed to meet the fast-paced and high-efficiency requirements of engineering construction, these prepackaged magnesium anodes are often used for the cathodic protection of buried metallic structures in a range of soil resistivities; such as pipelines, underground tanks and external tank bases as well as other similar structures.

Additional information

| Application | Pipelines, Foundations, Storage Tank |

|---|---|

| Environment | Soil |

Description

Description

Quality Substrate Material

The bare magnesium anode is casted from high-purity magnesium and has two alloy types available with varying electrode potential (relative to a Cu/CuSO4 reference electrode).

1. Standard Magnesium Alloy Anode

The standard potential(H1) anode is manufactured in accordance with ASTM B843 – AZ63B standard, containing 90% Magnesium, 6% Aluminum and 3% Zinc. The zinc and aluminum elements are used to lower the cost of the anode, however, they do also lower the driving potential to about -1.55 volts (relative to a Cu/CuSO4 reference electrode). This product is ideal for soil conditions where resistivity is under 20 Ω.m.

2. High Potential Magnesium Alloy Anode

The high potential anode is manufactured from 99% pure magnesium, according to ASTM B843 – M1C standard. It has higher open circuit voltage and driving potential than standard potential anode, with its open circuit potential being as high as -1.7 volts. The high driving voltage means greater protection can be provided by fewer anodes. Therefore, this anode is able to be used in a higher soil resistivity environment.

Environment-friendly Backfill

The added backfill helps to decrease the electrical resistance of the anode to the ground as well as retain moisture which allows for better efficiency and homogeneous consumption of the anode, thus creating an efficient anode bed. Our backfill is prepared with naturally degradable and recyclable materials in the following weight ratio*:

- Hydrated Gypsum: 75%

- Bentonite: 20%

- Sodium Sulphate: 5%

The content of harmful elements in the backfill is below the industrial safety standards, meaning it will not introduce any pollution to the surrounding environment.

- Cadmium ≤ 1 ppm

- Arsenicum ≤ 1 ppm

- Mercury ≤ 1 ppm

- Phosphorus ≤ 10 ppm

* Other specialized mixture compositions are available upon request.

Easy Installation

The prepackaged magnesium anode is appropriate for direct burial. This simplifies the on-site construction process, as some processes which traditionally took place on site (such as backfilling) are carried out in the factory prior to delivery, making for a convenient and fast installation. This helps to ensure the construction and installation quality of the anode ground bed remain consistent.

Multiple Cable Options

Our standard lead cable is 10ft. AWG #12 Solid THHN/THWN. Other options include PVC/PVC, XLPE/PVC, HMWPE or TW, which can be supplied in custom sizes, lengths and colors upon request. The cable can be connected by direct brazing, mechanical fastening or welding to ensure high pull strength and low connection resistance.

Parameters

We have developed a wide range of prepackaged magnesium anodes for various soil applications. Drawing from over 50 years production experience, Jennings Anodes have the capability to fully customize anode shape, size and service life to meet your desired specification upon request.

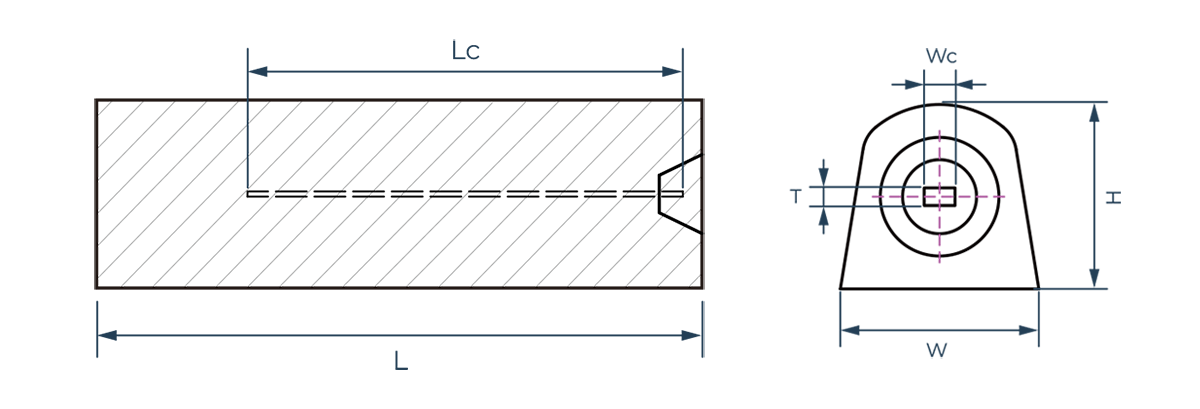

| Item No. | Anode Dimensions ( W x H x L ) | Insert Dimensions | Prepackaged Size | Weight | ||||

| High Potential | Standard Potential | Wc | T | Diameter | Length | Bare | Prepackaged | |

| JA-MG-B5D2 |

2.8” x 3.0” x 12.2”

(70 x 76 x 310 mm) |

2.8” x 3.0” x 12.0”

(70 x 76 x 305 mm) |

0.6”

(14 mm) |

0.06”

(1.5 mm) |

5”

(127 mm) |

17.7”

(450 mm) |

5 lbs

(2.3 kg) |

18 lbs

(8.2 kg) |

| JA-MG-B5D3 |

3.5” x 3.7” x 7.5”

(89 x 95 x 190 mm) |

3.5” x 3.7” x 7.1”

(89 x 95 x 180 mm) |

0.6”

(14 mm) |

0.06”

(1.5 mm) |

6.3”

(160 mm) |

11.8”

(300 mm) |

5 lbs

(2.3 kg) |

17 lbs

(7.7 kg) |

| JA-MG-B9D2 |

2.8” x 3.0” x 21.5”

(70 x 76 x 545 mm) |

2.8” x 3.0” x 21.3”

(70 x 76 x 540 mm) |

0.6”

(14 mm) |

0.06”

(1.5 mm) |

5.5”

(140 mm) |

27.2”

(690 mm) |

9 lbs

(4.1 kg) |

35 lbs

(16 kg) |

| JA-MG-B9D2-1 |

2.5” x 2.6” x 25.6”

(63.5 x 67 x 650 mm) |

2.5” x 2.6” x 25.2”

(63.5 x 67 x 640 mm) |

0.6”

(14 mm) |

0.06”

(1.5 mm) |

5.1”

(130 mm) |

31.9”

(810 mm) |

9 lbs

(4.1 kg) |

55 lbs

(25 kg) |

| JA-MG-B9D3 |

3.5” x 3.7” x 13.6”

(89 x 95 x 345 mm) |

3.5” x 3.7” x 12.8”

(89 x 95 x 325 mm) |

0.6”

(14 mm) |

0.06”

(1.5 mm) |

6.3”

(160 mm) |

21.7”

(550 mm) |

9 lbs

(4.1 kg) |

27 lbs

(12.3 kg) |

| JA-MG-B14D2 |

2.8” x 3.0” x 33.5”

(70 x 76 x 850 mm) |

2.8” x 3.0” x 32.1”

(70 x 76 x 815 mm) |

0.6”

(14 mm) |

0.06”

(1.5 mm) |

5.5”

(140 mm) |

37.4”

(950 mm) |

14 lbs

(6.36 kg) |

48.5 lbs

(22 kg) |

| JA-MG-B17D2 |

2.5” x 2.6” x 47.6”

(63.5 x 67 x 1210 mm) |

2.5” x 2.6” x 46.8”

(63.5 x 67 x 1188 mm) |

0.6”

(14 mm) |

0.06”

(1.5 mm) |

5.5”

(140 mm) |

53.1”

(1350 mm) |

17 lbs

(7.7 kg) |

68 lbs

(31 kg) |

| JA-MG-B17D3 |

3.5” x 3.7” x 25.4”

(89 x 95 x 645 mm) |

3.5” x 3.7” x 24.0”

(89 x 95 x 610 mm) |

0.6”

(14 mm) |

0.06”

(1.5 mm) |

6.3”

(160 mm) |

30.7”

(780 mm) |

17 lbs

(7.7 kg) |

45 lbs

(20.4 kg) |

| JA-MG-B17D4 |

4.0” x 4.3” x 20.7”

(102 x 108 x 525 mm) |

—— |

0.6”

(14 mm) |

0.06”

(1.5 mm) |

7.5”

(190 mm) |

26.8”

(680 mm) |

17 lbs

(7.7 kg) |

62 lbs

(28 kg) |

| JA-MG-B20D2 |

2.8” x 3.0” x 60.0”

(70 x 76 x 1524 mm) |

2.8” x 3.0” x 58.9”

(70 x 76 x 1495 mm) |

0.6”

(14 mm) |

0.06”

(1.5 mm) |

5.5”

(140 mm) |

65.0”

(1650 mm) |

20 lbs

(9.1 kg) |

84 lbs

(38 kg) |

| JA-MG-B32D5 |

5.5” x 5.7” x 19.6”

(140 x 146 x 498 mm) |

5.5” x 5.7” x 18.6”

(140 x 146 x 472 mm) |

0.8”

(20 mm) |

0.08”

(2 mm) |

7.9”

(200 mm) |

26.8”

(680 mm) |

32 lbs

(14.5 kg) |

70 lbs

(31.8 kg) |

| JA-MG-B48D5 |

5.5” x 5.7” x 29.5”

(140 x 146 x 750 mm) |

5.5” x 5.7” x 28.0”

(140 x 146 x 710 mm) |

0.8”

(20 mm) |

0.08”

(2 mm) |

8.1”

(205 mm) |

37.8”

(960 mm) |

48 lbs

(21.8 kg) |

100 lbs

(45.4 kg) |

| JA-MG-B60D4 |

4.4” x 4.4” x 60.0”

(112 x 112 x 1524 mm) |

4.5” x 4.5” x 58.5”

(114 x 114 x 1485 mm) |

0.8”

(20 mm) |

0.12”

(3 mm) |

7.5”

(190 mm) |

65.0”

(1650 mm) |

60 lbs

(27.3 kg) |

150 lbs

(68 kg) |

Testing Details

We employ ISO 9001:2015 quality management system and rigorous internal testing standards to ensure the optimum lifespan and performance of our anodes. Each anode is labelled with a unique serial number for quality tracking.

| Technical Measurement | Chemical Composition | Electrochemical Performance | Physical Properties |

| Testing Standard | ATSM A518 (Gr1) | ATSM A518 (Gr3) | Foundry ITP |

| Testing Content | Chemical Analysis | Circuit Potential / Anode Resistance / Current Efficiency | Surface Finish / Dimension & Weight / Steel Core / Cable Connection / Sealing / Backfill Packaging |

| Equipments | Optical Emission Spectrometer OBLF QSN 750 | Electrochemical Analyzer EPI 200 | Calibrated Digital Measuring Devices |

Packaging Information

| Item No. |

Anode Qty

(per pallet) |

Pallet Dimensions

(L x W x H) |

N.W. | G.W. |

Pallet Qty

(per 20ft. container) |

| JA-MG-B17D3 | 50 | 46.5” x 42.5” x 40.5” (1180 x 1080 x 1030 mm) | 2478 lbs (1125 kg) | 2600 lbs (1180 kg) | 18 |

| JA-MG-B20D2 | 20 | 72” x 32” x 25” (1830 x 810 x 630 mm) | 1695 lbs (770 kg) | 1805 lbs (820 kg) | 21 |

| JA-MG-B32D5 | 40 | 43.5” x 45” x 42.5” (1110 x 1140 x 1080 mm) | 2687 lbs (1220 kg) | 2780 lbs (1270 kg) | 17 |

| JA-MG-B40D3 | 20 | 68” x 35.5” x 28.5” (1730 x 910 x 720mm) | 1785 lbs (810 kg) | 1895 lbs (860 kg) | 18 |

| JA-MG-B48D5 | 24 | 42.5” x 51.5” x 35” (1080 x 1310 x 890mm) | 2400 lbs (1090 kg) | 2522 lbs (1145 kg) | 16 |

Remarks: Custom packing is available upon request.

We have strict packing protocols to guarantee safe delivery of our products. Clear shipping marks and documentation make delivery acceptance straightforward and simple.

Shipping Documents:

- Proforma invoice

- Packing list

- Testing reports (Chemical Composition, Electrochemical Properties Test, Certificate of Compliance)

- Certificate of origin (upon request)